Roof Coating are a great alternative to conventional reroofs

Hybrid Karnak Roof Coating

AAM Roofing & Construction proudly installs roof coatings on flat roofs, exposed fastener metal panel roofs and other repairs. AAM has mostly installed Karnak Coatings in the past. Local support and representation is great. Other viable products in the Denver market sold thru local distribution include Gaco and GE Silicon. There are many other manufacturers that sell direct and have very viable products.

While most coatings come in both Acrylic as well as Silicon, GE only offers Silicon based products. Silicon is a great product and works especially well in challenging situations like ponding areas. The main draw back with silicon is most products will not adhere to silicon when it is applied. If silicon is applied and in the future it needs to be modified or repaired, silicon must be used for the repair. This is often the case with many products. Many roofing sheets are incompatible with other sheets.

Karnak offers both Acrylic and Silicon based solutions. In some cases, hybrid systems are installed mixing the two. With hybrid systems, acrylic material is applied of the majority of the roof and applied first. In some of the trouble areas ( e.g. ponding ), silicon is applied. The acrylic is applied first because the acrylic will not adhere to silicon. The silicon will adhere to the acrylic. The cost of acrylic is generally lower. Acryilic is a more friendly to clean up and seems to dry faster leading to faster application. Many applications require more than one coat.

The application process of Acrylic and Silicon is similar. The first step in applying either is a very rigorous cleaning. This includes a cleaning solution provided by Karnak, a good stiff deck brush and a pressure washer.

Karnak Preperation Power Wash

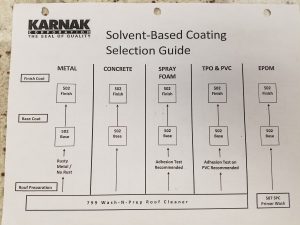

Karnak Solvent Selection Guide

Most roofing products are cleaned with concentrated Karnak 799 wash which may be similar to TSP cleaning solution.

Karnak 799 Wash

Coatings are often applied to asphalt roofing, modified bitimun, , metal panel, PVC, TPO, EPDM and others. Modified bitimun asphalt roof cleaning is typically not as challenging as some. EPDM has a special cleaning product that etches the surface and can lead to dirty black water when rinsed off that can stain areas where it runs off so beware. EPDM requires more elbow grease and a special cleaner ( 507 ) to get a clean surface. The picture show some of the dirty water that drained down from an EPDM roof to this mod bit roof.

EPDM Cleaning Solution 507

Dirt and buildup adheres well to EPDM and it can be challenging to get an old EPDM roof adequately clean. If the roof is on a restaurant, special consideration will have to be applied to animal fat residue. In some cases an animal fat resistant sheet may be applied over the cleaned area to eliminate the grease if it cannot be completely cleaned. Once all surfaces are clean, detail work is performed. Any opening or loose seam must have a mastic solution applied with a cotton mesh.

Karnak Cotton Membrane and chip brush

In karnak’s case, the mastic is white and is called Karnaflex.

Karnakflex WB Mastic

Karnaflex Application

Water based products are not always great, but in Karnak’s karnaflex it works great. Adhesion is good and it applies very well. Water based products are typically easier to clean. The general roof of where to apply the karnflex is that if the opening is large enough to slide a credit card into a little bit, it should be detailed. A 3″ disposable chip brush works great applying the Karnaflex product. Karnak instructions call for a primer coating of the entire surface once all details have been completed. This can be applied with a typical 9″ painting roller.

Karnak Common Tools

Karnak has specific application rates for both the primer and the final top coat. Failing to follow the guidelines will result in poor performance. The primer is offwhite. This helps when applying the final coat. The visual difference in color helps to see what areas have not received a final coat. The final coat is the last step. Again, it very important to follow the application rates. In the end, a specific mil thickness needs to be the goal.

Hybrid Karnak Roof Coating

Karnak offers very good warranties and onsite inspections and guidance. Warranty programs offer leak guarantees as well as material warranties. Guarantees against leaks are an additional cost, but relatively minor considering peace of mind. Premium warranties also provide inspections by a qualified independent representative assuring you of proper installation.